martin0reg

Printer Master

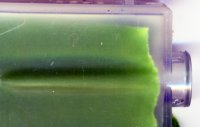

There is a series of pictures by mikling which shows very clear how the lower and upper sponge/fiber works in practice, how they are sucking ink and not dripping, and that the upper is more hydrophobic than the lower because the upper is for breathing/air exchange while only the lower is for ink transfer from reservoir to outlet...

http://www.printerknowledge.com/threads/do-i-have-a-problem-with-dry-sponges.6058/page-7

First the upper sponge would "empty" - while it looks saturated it is not. Then the reservoir would empty - now the upper sponge is only for "breathing" and the lower transfers the ink

PS: and for the scientists among us in post #93 there is a link to the canon cartridge patent, exhaustive reading...

http://www.printerknowledge.com/threads/do-i-have-a-problem-with-dry-sponges.6058/page-7

First the upper sponge would "empty" - while it looks saturated it is not. Then the reservoir would empty - now the upper sponge is only for "breathing" and the lower transfers the ink

PS: and for the scientists among us in post #93 there is a link to the canon cartridge patent, exhaustive reading...

Last edited: