- Joined

- Nov 27, 2010

- Messages

- 5,129

- Reaction score

- 5,009

- Points

- 373

- Location

- Copenhagen Denmark

- Printer Model

- Canon MP990

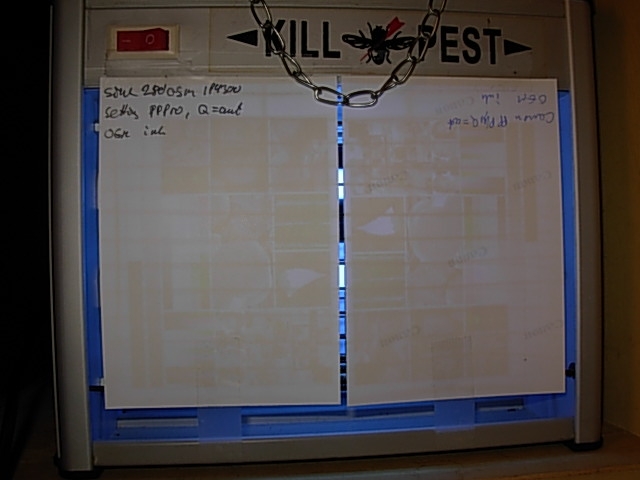

Here are the results after one week of UV exposure. I attached four A6 prints to the bug zapper, Canon CLI-8 ink on Canon PP101 270 gsm paper and on Sihl glossy 280 gsm paper, and IS ink for CLI-521 on Canon PP101 270 gsm paper and on Sihl glossy 280 gsm paper.

For the Canon OEM ink an iP4300 was used, for the IS ink an MP540 was used and for the scans an Epson V33 scanner was used. I had to tweak the scanner settings to get a result fairly similar to what I see. The same settings were used for both scans.

The reason for using A6 format is the size of the bug zapper, so four prints could be attached, two on the front and two on the back :

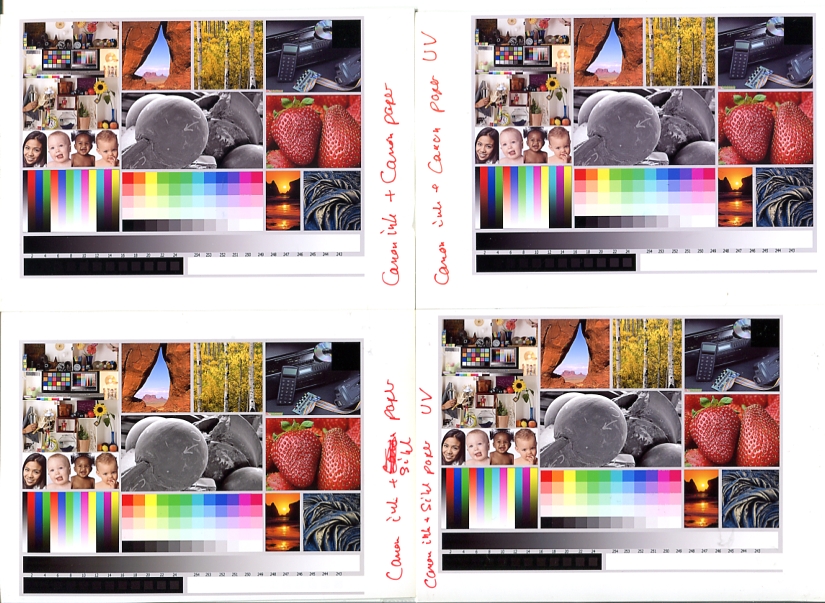

Here are the results for Canon OEM CLI-8 ink, upper left is Canon ink + Canon paper with no UV exposure, upper right is Canon ink + Canon paper after UV exposure, lower left is Canon ink + Sihl paper with no UV exposure and lower right is Canon ink + Sihl paper after UV exposure:

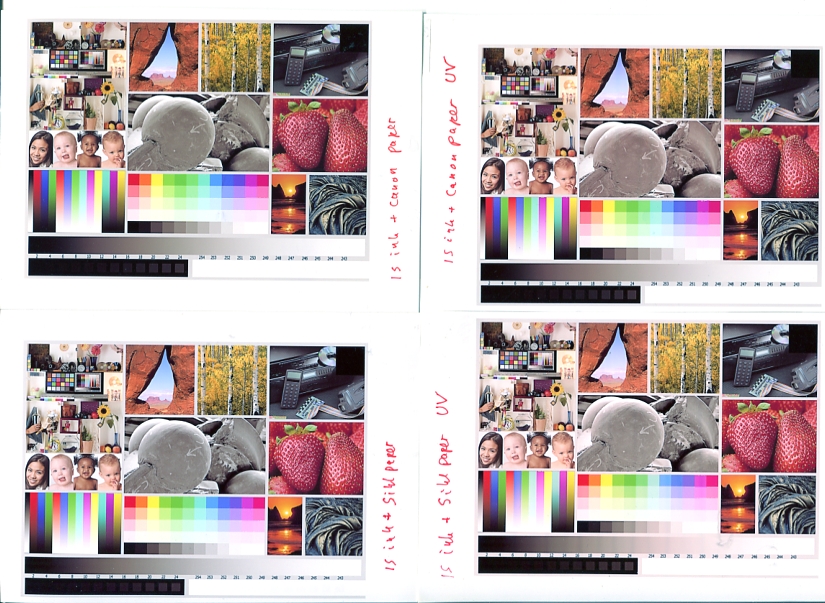

Here are the results for IS inks for CLI-521, upper left is IS ink + Canon paper with no UV exposure, upper right is IS ink + Canon paper after UV exposure, lower left is IS ink + Sihl paper with no UV exposure and lower right is IS ink + Sihl paper after UV exposure:

It is seen that the fading is more dependent on the ink than on the paper. As expected the winning combination is Canon OEM ink and Canon OEM paper. It looks like the ink that faded the most is IS Cyan 244 on Sihl paper. This is determined by looking at the grey-scales and the B/W image in the middle of the prints. They are shifted towards red, meaning cyan has been weakened.

I'm glad to see that the bug zapper can be used for fading tests, even if it is a bit slow. I'll re-attach the prints and continue the test. If the fading continues, I'll post the results.

For the Canon OEM ink an iP4300 was used, for the IS ink an MP540 was used and for the scans an Epson V33 scanner was used. I had to tweak the scanner settings to get a result fairly similar to what I see. The same settings were used for both scans.

The reason for using A6 format is the size of the bug zapper, so four prints could be attached, two on the front and two on the back :

Here are the results for Canon OEM CLI-8 ink, upper left is Canon ink + Canon paper with no UV exposure, upper right is Canon ink + Canon paper after UV exposure, lower left is Canon ink + Sihl paper with no UV exposure and lower right is Canon ink + Sihl paper after UV exposure:

Here are the results for IS inks for CLI-521, upper left is IS ink + Canon paper with no UV exposure, upper right is IS ink + Canon paper after UV exposure, lower left is IS ink + Sihl paper with no UV exposure and lower right is IS ink + Sihl paper after UV exposure:

It is seen that the fading is more dependent on the ink than on the paper. As expected the winning combination is Canon OEM ink and Canon OEM paper. It looks like the ink that faded the most is IS Cyan 244 on Sihl paper. This is determined by looking at the grey-scales and the B/W image in the middle of the prints. They are shifted towards red, meaning cyan has been weakened.

I'm glad to see that the bug zapper can be used for fading tests, even if it is a bit slow. I'll re-attach the prints and continue the test. If the fading continues, I'll post the results.

Last edited: