- Joined

- Jan 18, 2010

- Messages

- 15,907

- Reaction score

- 8,917

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Canon/3D, CR-10, CR-10S, KP-3

Those of you that choose to use OEM inks are at a terrible disadvantage when it comes to changing their empty cartridges for a new one, WHY you may ask... ?

The user tends to wait till the cartridge is declared completely empty in an attempt to use up all of the ink and they then think that they are been very economical and prudent by using every drop of this expensive OEM liquid. !

This effort on their part seems to make perfect sense till you consider what (The 3rd party ink users) commonly calls the dreaded Domino Factor, and how can an OEM user stop this wasteful practice that Canon employs to squeeze their most loyal OEM ink users even more.

The OEM user replaces the one empty cartridge at a time, which the machine then duly responds by automatically doing a maintenance cleaning cycle, that then can cause another cartridge to become empty and so the user now replaces that cartridge too, only to find they have unwittingly entered the Domino syndrome which as we know, wastes an awful lot of expensive ink.

Up till now it didn’t seem possible to prevent this, but with a bit of prudence and new practice, the OEM user can also employ the same technique that the refillers uses to get out of the Twilight Zone of waste ink.

It goes like this...

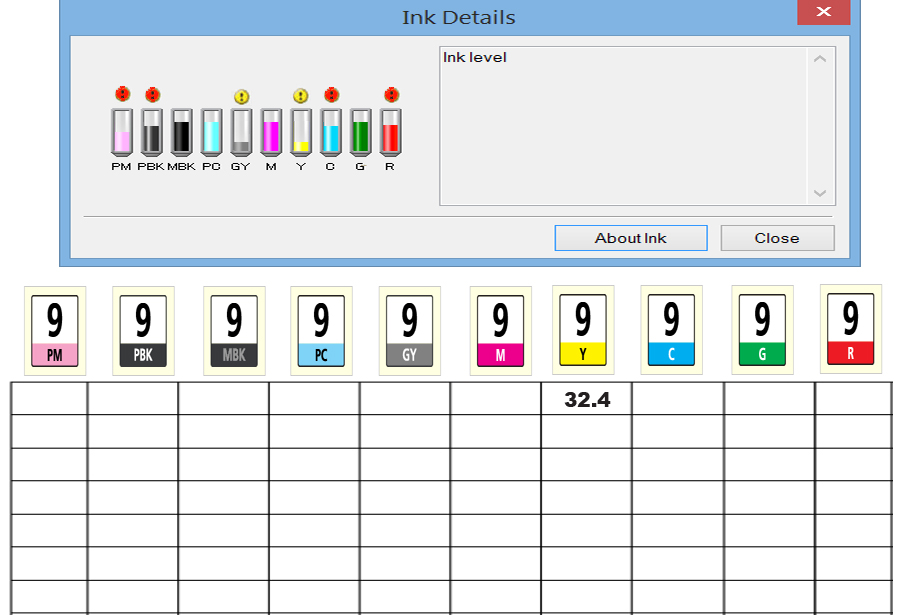

When they get the first signs of a low ink cartridge, (Marked in Yellow) they should immediately change that particular cartridge and any other cartridge that is on or below half full (Marked in red) with nice fresh new cartridges.

Now this is where the savings come in, because we know that a new cartridge weighs in at approx. 34 gm give or take a decimal point, so if you reset the used cartridges and weight them and write in the details in a chart similar to the one below and keep them safe for use at a later date, not forgetting to fit the orange clip back on the bottom of the cartridge to keep the ink fresh.

When you have accumulated several sets of used cartridges, you can reuse the remaining ink in each cartridge to refill as many of the other partially filled cartridges as possible, by employing this practice you’ll have managed to save quite a lot of ink that would have otherwise been wasted ink...

The ink Details below are altered and are for illustration purposes only...

This chart was inspired by @dannno’s spreadsheet idea...

http://www.printerknowledge.com/threads/a-simple-spreadsheet.11048/

To take the speculation out of how much ink is wasted and how often, then fit a Waste Potty, its acts as an excellent ink monitoring, that is if you really want to accurately know...

The user tends to wait till the cartridge is declared completely empty in an attempt to use up all of the ink and they then think that they are been very economical and prudent by using every drop of this expensive OEM liquid. !

This effort on their part seems to make perfect sense till you consider what (The 3rd party ink users) commonly calls the dreaded Domino Factor, and how can an OEM user stop this wasteful practice that Canon employs to squeeze their most loyal OEM ink users even more.

The OEM user replaces the one empty cartridge at a time, which the machine then duly responds by automatically doing a maintenance cleaning cycle, that then can cause another cartridge to become empty and so the user now replaces that cartridge too, only to find they have unwittingly entered the Domino syndrome which as we know, wastes an awful lot of expensive ink.

Up till now it didn’t seem possible to prevent this, but with a bit of prudence and new practice, the OEM user can also employ the same technique that the refillers uses to get out of the Twilight Zone of waste ink.

It goes like this...

When they get the first signs of a low ink cartridge, (Marked in Yellow) they should immediately change that particular cartridge and any other cartridge that is on or below half full (Marked in red) with nice fresh new cartridges.

Now this is where the savings come in, because we know that a new cartridge weighs in at approx. 34 gm give or take a decimal point, so if you reset the used cartridges and weight them and write in the details in a chart similar to the one below and keep them safe for use at a later date, not forgetting to fit the orange clip back on the bottom of the cartridge to keep the ink fresh.

When you have accumulated several sets of used cartridges, you can reuse the remaining ink in each cartridge to refill as many of the other partially filled cartridges as possible, by employing this practice you’ll have managed to save quite a lot of ink that would have otherwise been wasted ink...

The ink Details below are altered and are for illustration purposes only...

This chart was inspired by @dannno’s spreadsheet idea...

http://www.printerknowledge.com/threads/a-simple-spreadsheet.11048/

To take the speculation out of how much ink is wasted and how often, then fit a Waste Potty, its acts as an excellent ink monitoring, that is if you really want to accurately know...