- Joined

- Apr 19, 2007

- Messages

- 8,706

- Reaction score

- 7,177

- Points

- 393

- Location

- USA

- Printer Model

- Canon MB5120, Pencil

Last night I duplex printed an 10 page article that has numerous brown bars 5/16 inch tall and of variable lengths. These solid colored bars are above every table, graph and chart in the articles I print. I have not noticed this behavior with other solid colored horizontal bars before, but maybe that is because I don't recall this particular colored used.

On the last 4 or 5 pages I noticed a faint repeating two-tone banding of approximately 0.5 inch length. The appearance is similar to the banding effect of using a CIS scanner element in default mode. See PeterBJ's post here for example and the fix. (Hat tip to original poster @lukasz) Now that the ink has dried overnight it is essentially imperceptible unless you are looking for it.

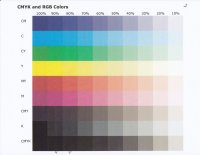

Maybe this is evidence of the ink starvation others experience. Will try printing the stress test pages on this page to see what happens. A call to Canon may be forthcoming.

On the last 4 or 5 pages I noticed a faint repeating two-tone banding of approximately 0.5 inch length. The appearance is similar to the banding effect of using a CIS scanner element in default mode. See PeterBJ's post here for example and the fix. (Hat tip to original poster @lukasz) Now that the ink has dried overnight it is essentially imperceptible unless you are looking for it.

Maybe this is evidence of the ink starvation others experience. Will try printing the stress test pages on this page to see what happens. A call to Canon may be forthcoming.