- Joined

- Nov 3, 2004

- Messages

- 3,081

- Reaction score

- 1,452

- Points

- 337

- Location

- Bay Area CA

- Printer Model

- CR-10, i560 ,MFC-7440N

I really would like to keep my 3D printing limited to stuff that I "need" and try to avoid as much junk / trinkets as possible!

I've been wracking my brain to think of something to build from scratch, and I think I came up with an idea!

The "nut" on our toilet seat is broken and hard to access. I was thinking I could print a replacement... but that's boring. I want to DESIGN the perfect replacement!!!

So, here's what I did so far (even before getting my printer which will come tomorrow):

That made the nut easy to access and only the bottom part is threaded!

Then I thought: "It would be cool to be able to tighten this by hand"... so I downloaded / imported this wingnut: https://www.thingiverse.com/thing:716147

... then resized it and grouped it with my existing extension and hole, which gave me this:

I'm pretty dang excited!

I think I'm going to do like @The Hat did on his nut project and only print the first bit to make sure it fits the bolt before I commit to a full printing.

I also need to decide if I really want the wings on there since I may want to just use a wrench, the wings may get in the way of the toilet bowl, and I may need to build-in supports to hold up the wings during printing... which I'd like to avoid (wasted material and a pain).

I can't wait to get my printer tomorrow and give this a try!

I've been wracking my brain to think of something to build from scratch, and I think I came up with an idea!

The "nut" on our toilet seat is broken and hard to access. I was thinking I could print a replacement... but that's boring. I want to DESIGN the perfect replacement!!!

So, here's what I did so far (even before getting my printer which will come tomorrow):

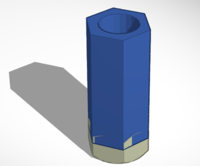

- Logged into www.tinkercad.com

- Downloaded this nut and imported it:https://www.thingiverse.com/thing:537094 (I didn't want to bother with thread sizing, etc. so I cheated on this)

- Inserted a new "polygon" shape and made it fit the same size as the nut

- Hollowed out the middle of the polygon

- Final result:

That made the nut easy to access and only the bottom part is threaded!

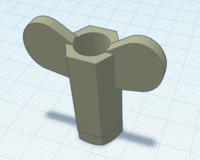

Then I thought: "It would be cool to be able to tighten this by hand"... so I downloaded / imported this wingnut: https://www.thingiverse.com/thing:716147

... then resized it and grouped it with my existing extension and hole, which gave me this:

I'm pretty dang excited!

I think I'm going to do like @The Hat did on his nut project and only print the first bit to make sure it fits the bolt before I commit to a full printing.

I also need to decide if I really want the wings on there since I may want to just use a wrench, the wings may get in the way of the toilet bowl, and I may need to build-in supports to hold up the wings during printing... which I'd like to avoid (wasted material and a pain).

I can't wait to get my printer tomorrow and give this a try!