Anyone considering purchasing this series of printers are a glutton for punishment. My first experience with these printers was not good about three years ago. It took three machines from Epson before I finally got one that produced a proper nozzle check out of the box with one head clean. The first one emptied the set of cartridges and could not produce even ONE proper nozzle check. So read carefully the above it was not the ink nor the cartridges that were faulty but the aspect that Epson designed this series of printers so that aftermarket users would have hell and they succeeded. Yes, you are going to get one that is good and then it goes bad because the EXACT tolerances for the ink delivery system, is hard to meet. I still have an XP610 that I have managed to keep alive but there will come a day when it will fail. And YES, I have to refill the OEM in order to keep it there. The aftermarket refillable carts will bring that day of reckoning sooner.

So this last Black Friday, I saw a deal from Epson that allowed me to acquire a successor of the 1430 of sorts. Took delivery and sure enough. BAM. Six head cleans later, still have not produced a proper nozzle check AND the cartridges are near depleted.

There is also a longer story to this about how Epson has cleverly designed the system so that you actually get less than 30% of the ink to print in real usage.

So unless you are a glutton for punishment. I would recommend you think long and hard about WHY you really want to own these machines.

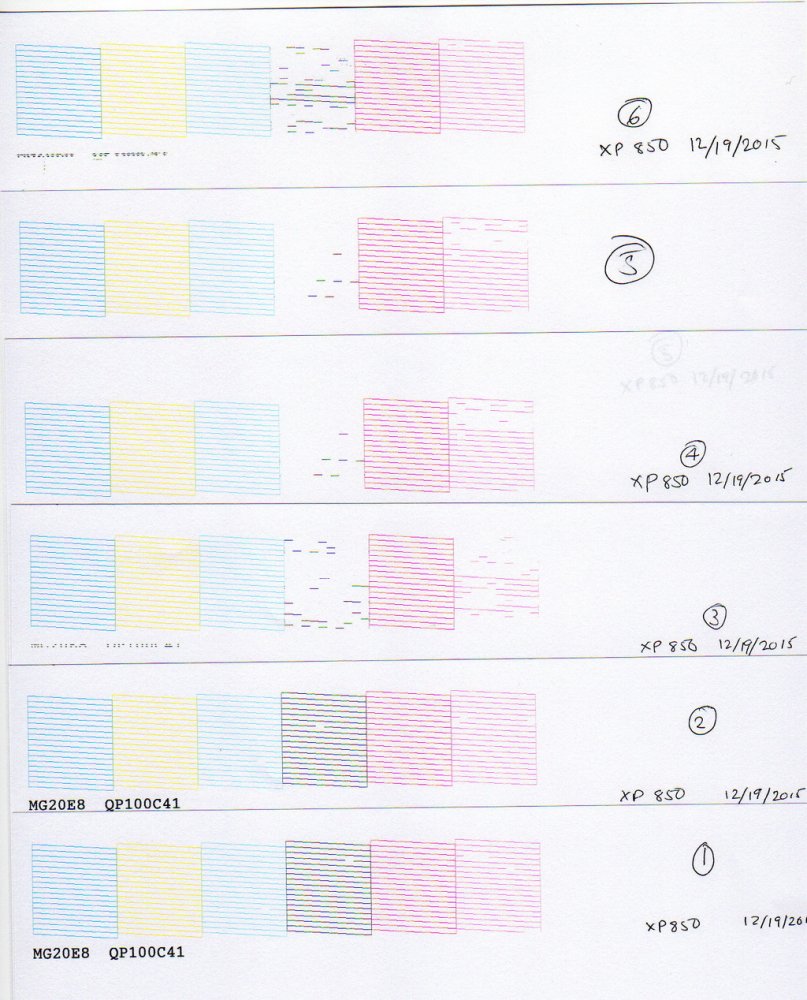

It is the weekend. I will place a call to Epson on Monday. In the meantime, enjoy the nozzle check I have submitted in sequence of 1 to 6. Again, think long and hard why you really want one of these machines. Epson has outengineered themselves on this series. So what is causing this? I mention the tolerances and it is precisely that. These cartridges are are designed similar to the Canon PGI-9 and PGI-72 but are a little more evolved in their design to thwart refilling back to the original. It is not the second aspect that is causing the problem but likely that Epson is unable to maintain the tight tolerances required when such a design in incorporated into a piezo printhead. So what is happening is that the film of ink that bonds the contact of the cartridge and printhead is breaking down and is allowing air to enter into the printhead. In prior Epson carts we are used to seeing secure high pressure seals, but these allow CIS units to be used successfully. No more of that says Epson. The tight specification engineering wise to maintain that bridge is not reliably maintained even by Epson at times. It could be the assembly of the cart, a spring that is too strong or even the material used in the pad. But even Epson cannot maintain that tight spec properly with their own ink and carts. See yourself chancing aftermarkets? And yes, after six head cleans, my waste ink tank is likely 20-25% full and not even one page has been printed.

I am having a hell of a week with Epson. Yesterday, I had to take in my SP 3880 to the Epson

doctors for adjustments due to the famous ERROR CODE 150C. It is out of warranty.

doctors for adjustments due to the famous ERROR CODE 150C. It is out of warranty.

So this last Black Friday, I saw a deal from Epson that allowed me to acquire a successor of the 1430 of sorts. Took delivery and sure enough. BAM. Six head cleans later, still have not produced a proper nozzle check AND the cartridges are near depleted.

There is also a longer story to this about how Epson has cleverly designed the system so that you actually get less than 30% of the ink to print in real usage.

So unless you are a glutton for punishment. I would recommend you think long and hard about WHY you really want to own these machines.

It is the weekend. I will place a call to Epson on Monday. In the meantime, enjoy the nozzle check I have submitted in sequence of 1 to 6. Again, think long and hard why you really want one of these machines. Epson has outengineered themselves on this series. So what is causing this? I mention the tolerances and it is precisely that. These cartridges are are designed similar to the Canon PGI-9 and PGI-72 but are a little more evolved in their design to thwart refilling back to the original. It is not the second aspect that is causing the problem but likely that Epson is unable to maintain the tight tolerances required when such a design in incorporated into a piezo printhead. So what is happening is that the film of ink that bonds the contact of the cartridge and printhead is breaking down and is allowing air to enter into the printhead. In prior Epson carts we are used to seeing secure high pressure seals, but these allow CIS units to be used successfully. No more of that says Epson. The tight specification engineering wise to maintain that bridge is not reliably maintained even by Epson at times. It could be the assembly of the cart, a spring that is too strong or even the material used in the pad. But even Epson cannot maintain that tight spec properly with their own ink and carts. See yourself chancing aftermarkets? And yes, after six head cleans, my waste ink tank is likely 20-25% full and not even one page has been printed.

I am having a hell of a week with Epson. Yesterday, I had to take in my SP 3880 to the Epson