- Joined

- Nov 27, 2010

- Messages

- 5,139

- Reaction score

- 5,022

- Points

- 373

- Location

- Copenhagen Denmark

- Printer Model

- Canon MP990

The red cartridge LED serves two purposes. It indicates the amount of ink in the cartridge to the user, but it is also read by a sensor in the printer after you close the lid after having installed a cartridge. If the sensor detects no light from the cartridge you get an error message that a cartridge cannot be detected.

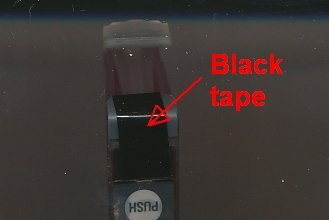

You can test this function by covering the end of the light guide at the top of an OEM cartridge with black electricians tape and reinserting the cartridge in the printer. You will then get en error message that a cartridge cannot be recognised. After removal of the tape, the cartridge is recognised again. I have just done this test on an MP970 and the test works.

I tried to scan a taped cartridge, not the best image:

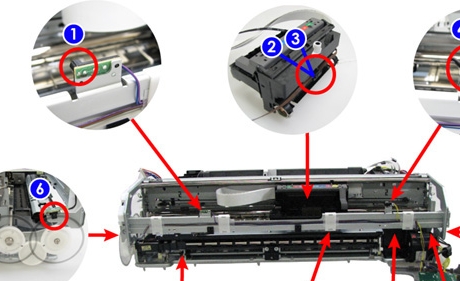

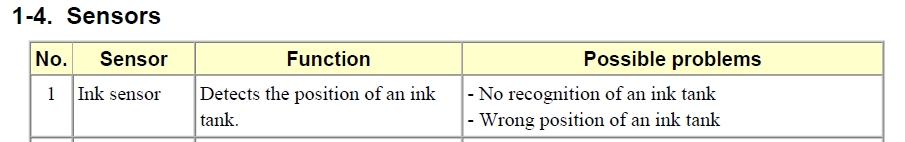

Here is a crop of a picture from the Pro 9500 MKII service manual showing sensors. The sensor marked "1" is the ink sensor that detects the red LEDS on the cartridges:

And the explanation from the service manual of the sensor "1":

I would have thought that the chips were sufficient for ink tank recognition, but the red cartridge LEDs are also needed. So it looks to me like @The Hat is right.

IIRC Canon once tried to get the use of red LEDs on compatible cartridges banned because of a patent violation. Not because of the function as a visual indicator but because of its role in ink tank detection. Some compatible cartridges became available with IR LEDs and an instruction of how to remove an IR stop filter from the ink sensor. I think I read this on the Druckerchannel.de website.

Edit: The Druckerchannel article is here, and a translation is here.

To get back on topic:

If you own a Canon printer for which a resetter exists you are privileged. Study the Epson forum and see how many problems compatible cartridges cause. The use of compatible cartridges with ARC chips is good "on the paper" but not always so in the real world. You can experience problems with ink starvation, ink leaking and the ARC chip getting out of sync with the ink amount in the cartridge. I have experienced these three problems when testing a set of after market refillable cartridges for PGI-550/CLI-551.

The use of OEM cartridges and a resetter for refilling is far better IMO. Disabling the ink level indication with the OEM cartridges to avoid the cost of a resetter is also a bad idea, as the cartridges are opaque and visual check of ink levels is not an option.

You can test this function by covering the end of the light guide at the top of an OEM cartridge with black electricians tape and reinserting the cartridge in the printer. You will then get en error message that a cartridge cannot be recognised. After removal of the tape, the cartridge is recognised again. I have just done this test on an MP970 and the test works.

I tried to scan a taped cartridge, not the best image:

Here is a crop of a picture from the Pro 9500 MKII service manual showing sensors. The sensor marked "1" is the ink sensor that detects the red LEDS on the cartridges:

And the explanation from the service manual of the sensor "1":

I would have thought that the chips were sufficient for ink tank recognition, but the red cartridge LEDs are also needed. So it looks to me like @The Hat is right.

IIRC Canon once tried to get the use of red LEDs on compatible cartridges banned because of a patent violation. Not because of the function as a visual indicator but because of its role in ink tank detection. Some compatible cartridges became available with IR LEDs and an instruction of how to remove an IR stop filter from the ink sensor. I think I read this on the Druckerchannel.de website.

Edit: The Druckerchannel article is here, and a translation is here.

To get back on topic:

If you own a Canon printer for which a resetter exists you are privileged. Study the Epson forum and see how many problems compatible cartridges cause. The use of compatible cartridges with ARC chips is good "on the paper" but not always so in the real world. You can experience problems with ink starvation, ink leaking and the ARC chip getting out of sync with the ink amount in the cartridge. I have experienced these three problems when testing a set of after market refillable cartridges for PGI-550/CLI-551.

The use of OEM cartridges and a resetter for refilling is far better IMO. Disabling the ink level indication with the OEM cartridges to avoid the cost of a resetter is also a bad idea, as the cartridges are opaque and visual check of ink levels is not an option.

Last edited: