- Joined

- Jan 18, 2010

- Messages

- 15,914

- Reaction score

- 8,921

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Canon/3D, CR-10, CR-10S, KP-3

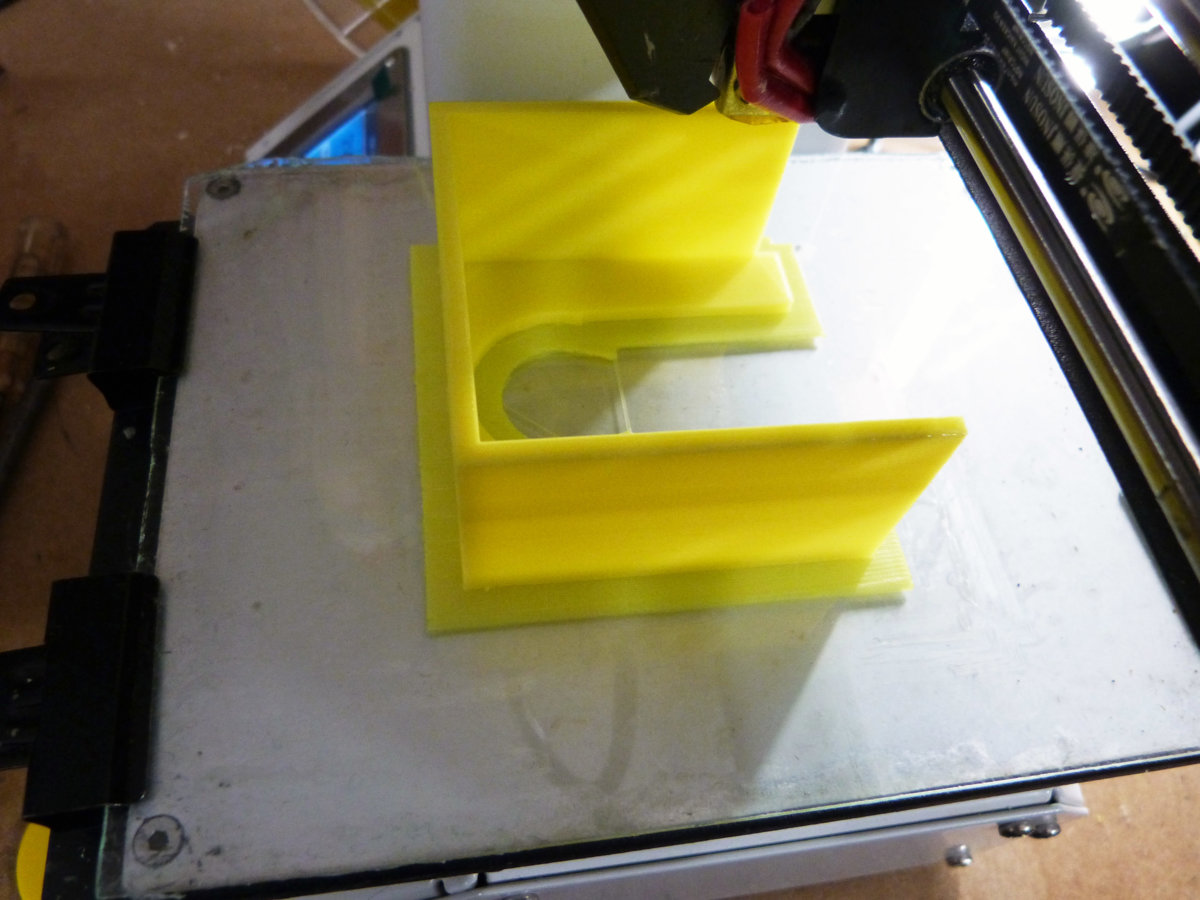

Since getting this 3D printer, it has been going steadily everyday now, my latest project is a covering box lid for my installed PIR.

I needed good strength in this box so I set the printer to high quality and its taking more than 24 hours to print, it has just finished right this minute and it fits like a glove, it was well worth waiting for.

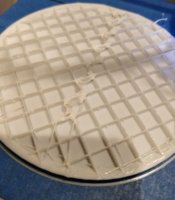

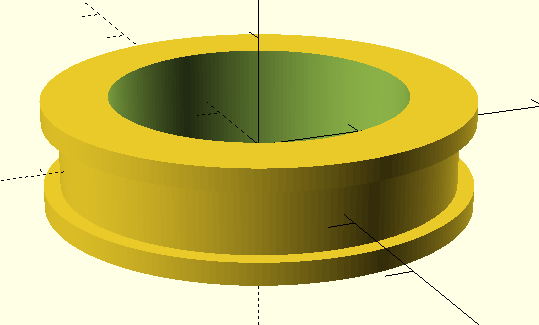

I still have a long waiting list of different projects that I’ve made up do, my next one is a covering ring for a bearing on Mrs The Hat sewing machine, I’ve had to installed a new drive belt on the sewing machine and it’s a bit slag so this ring will put more tension back on the belt...

I needed good strength in this box so I set the printer to high quality and its taking more than 24 hours to print, it has just finished right this minute and it fits like a glove, it was well worth waiting for.

I still have a long waiting list of different projects that I’ve made up do, my next one is a covering ring for a bearing on Mrs The Hat sewing machine, I’ve had to installed a new drive belt on the sewing machine and it’s a bit slag so this ring will put more tension back on the belt...