- Joined

- Jan 18, 2010

- Messages

- 15,914

- Reaction score

- 8,921

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Canon/3D, CR-10, CR-10S, KP-3

First off congratulation @Nifty on your first heated bed print, (Looks Great) but here, hand on a minute, ½ hour to heat the bed, that’s silly, and it sounds like your 12V power supply is not up to the job, it should only take 10 to 12 minutes on a slow day to heat the bed up, and 60c is a bit hot for PLA. (40c ish is better and safer)I had to clean off all the glue and REALLY clean the glass. I had a few mis-starts because the bed wasn't clean and hot enough. Once I had a super clean bed at 60 deg., it stuck just fine. My patience and effort was rewarded. I came back to the print after the bed had cooled and it had perfectly self-released. It was pretty epic. I can see how this can be addictive and why so many people do it this way. LOL!

My original power supply packed in and I bought another from Creality, (I think it was 30 Amp.) but never put it back into the control box, instead I have mine mounted on the wall and it hasn’t given a bit of trouble since, more than 3 years on, (Better cooling).

I tried glue sticks for a while and they worked great but needed to be re-apply for every use, but a bugger to clean off afterwards, the toughened glass I use has a rough surface and wont release the print till it cools a little bit.

I await my trials using the PEI steel sheet and if it’s as good at holding the print as the glass is then I’ll convert the smaller printer over to the PEI sheet too.

Tip:- I use two pieces of household tinfoil wrap under my glass sheet 25% and 50% smaller than the glass area and this gives me almost perfect flatness over the whole glass area, and I use manual levelling for best results..

To help hold your print to Glass use the 3DLAC as mentioned by @Redbrickman, its quicker cleaner and the spray can lasts for ages, and isn’t hard to clean off when you need to reapply more.. Hair spray is just adequate but not 100% every time, plus very messy to clean off.There is a spray called 3DLAC, not sure if it is sold on the other side of the pond You can also try hairspray, some swear by it, I swore at it

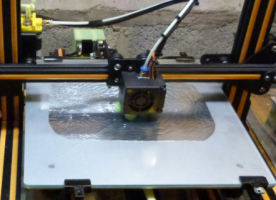

My first attempt laying foil under the clear glass.

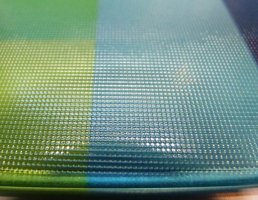

A close up of the glass surface..