Hector Vilches

Printing Ninja

- Joined

- Jan 9, 2016

- Messages

- 42

- Reaction score

- 69

- Points

- 80

- Location

- New Jersey

- Printer Model

- R2000, 3880, PRO-100, PRO-10

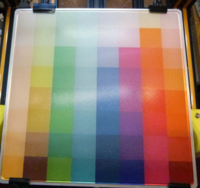

I was about to resurrect an old thread on bed adhesion and thought it might be even more beneficial to have a thread for different materials and surfaces. Here's my experience with PLA on an Ender 3 /w heated glass bed. Maybe I'll start a trend?

Isopropyl Alcohol pads: not good

I started with a glass bed and wiped it down with isopropyl alcohol... I thought this would get it the most clean it could be! I was wrong... didn't work too well. This must leave behind something that gets in the way of PLA adhesion, even though it is not visible to the eye.

Glue stick: good

Then I tried the glue stick liberally applied by rubbing the stick right on the bed, and while it worked, it didn't feel right to have all that glue messing up my nice smooth glass surface. After cleaning it all off again, I decided to apply the glue to a wet paper towel and deposit a super thin layer with the wet paper towel, leaving behind a 'matte' looking glass without any heavy streaks and this worked just as well and kept my OCD in check.

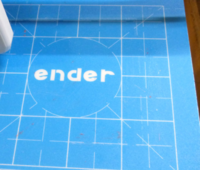

Soap and water cleaned glass bad: BEST

The glue stick works, but it wasn't super consistent and I wasn't happy with all the prep work. Along the way I found an Ivan Miranda video on the topic (https://www.youtube.com/watch?v=Kj4Xz3DwGSQ) and have not looked back... Wash the glass with soap and water, dry it, and never ever, ever, ever... touch it. It is super consistent and I have never had to pry a part off the bed. I just let it cool down and it lifts right off.

As always with this stuff, YMMV.

Isopropyl Alcohol pads: not good

I started with a glass bed and wiped it down with isopropyl alcohol... I thought this would get it the most clean it could be! I was wrong... didn't work too well. This must leave behind something that gets in the way of PLA adhesion, even though it is not visible to the eye.

Glue stick: good

Then I tried the glue stick liberally applied by rubbing the stick right on the bed, and while it worked, it didn't feel right to have all that glue messing up my nice smooth glass surface. After cleaning it all off again, I decided to apply the glue to a wet paper towel and deposit a super thin layer with the wet paper towel, leaving behind a 'matte' looking glass without any heavy streaks and this worked just as well and kept my OCD in check.

Soap and water cleaned glass bad: BEST

The glue stick works, but it wasn't super consistent and I wasn't happy with all the prep work. Along the way I found an Ivan Miranda video on the topic (https://www.youtube.com/watch?v=Kj4Xz3DwGSQ) and have not looked back... Wash the glass with soap and water, dry it, and never ever, ever, ever... touch it. It is super consistent and I have never had to pry a part off the bed. I just let it cool down and it lifts right off.

As always with this stuff, YMMV.