You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D.... 5 Lamps (Mark V)..!

- Thread starter The Hat

- Start date

ninj

Print Addict

- Joined

- Dec 28, 2011

- Messages

- 121

- Reaction score

- 153

- Points

- 193

Thinking I had solved the problem, I quickly rebuilt the light using the existing column that withstood the wind, with a plastic build (Infill 90%) and slid the new section over the still standing column to a depth of 30cm, But again the wind found the weak spot and it snapped it off.. Mark 4…

How many perimeters do you use?

- Thread starter

- #33

- Joined

- Jan 18, 2010

- Messages

- 16,105

- Reaction score

- 9,062

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Canon/3D, CR-10, CR-10S, KP-3

@Nini, Explain please ?... I'm lost...How many perimeters do you use?

ninj

Print Addict

- Joined

- Dec 28, 2011

- Messages

- 121

- Reaction score

- 153

- Points

- 193

I think in Cura they call it "wall thickness".@Nini, Explain please ?... I'm lost...

- Thread starter

- #35

- Joined

- Jan 18, 2010

- Messages

- 16,105

- Reaction score

- 9,062

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Canon/3D, CR-10, CR-10S, KP-3

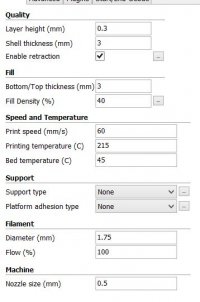

Straight from CURA.. Layer thickness .3mm.. Shell thickness .3mm..Layer height .3mm..

Fill Density on the old lamp was 90% and 35% 0n Johnny 5..

This will confuse the hell out of @stratman...

Fill Density on the old lamp was 90% and 35% 0n Johnny 5..

This will confuse the hell out of @stratman...

Last edited:

- Joined

- Apr 19, 2007

- Messages

- 8,706

- Reaction score

- 7,177

- Points

- 393

- Location

- USA

- Printer Model

- Canon MB5120, Pencil

Just like Australian rules football.This will confuse the hell out of @stratman...

Who's this Johnny 5? I know Jonny Quest and my cousin Johnny. Is Johnny 5 some robot from Doctor Who?

Last edited:

ninj

Print Addict

- Joined

- Dec 28, 2011

- Messages

- 121

- Reaction score

- 153

- Points

- 193

I'm also a bit confused because I'm not a Cura user. I was after the number of perimeters or wall thickness. If that's really 0.3mm then it would be less than the normal 0.4 nozzle, so it probably means something else. Reason I asked, I remember seeing some strength testing and it turned out that increasing the number of perimeters was more effective than increasing the infill. Something like 4-6 perimeters (or >2mm) should be nice and strong.Straight from CURA.. Layer thickness .3mm.. Shell thickness .3mm..Layer height .3mm..

Fill Density on the old lamp was 90% and 35% 0n Johnny 5..

This will confuse the hell out of @stratman...

- Thread starter

- #38

- Joined

- Jan 18, 2010

- Messages

- 16,105

- Reaction score

- 9,062

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Canon/3D, CR-10, CR-10S, KP-3

I have been calling the Mark 5 lamp standard Johnny 5 since its inception, so you must have been on holidays a long time..Who's this Johnny 5? I know Jonny Quest and my cousin Johnny. Is Johnny 5 some robot from Doctor Who?

This is what I have and use and that’s it, but I’m quite happy with the results, if I could increase them more I would.. The more help the better..If that's really 0.3mm then it would be less than the normal 0.4 nozzle, so it probably means something else. Reason I asked, I remember seeing some strength testing and it turned out that increasing the number of perimeters was more effective than increasing the infill.

ninj

Print Addict

- Joined

- Dec 28, 2011

- Messages

- 121

- Reaction score

- 153

- Points

- 193

Shell thickness looks good - 3mm (rather than 0.3mm), which makes good sense for your lamp.

- Thread starter

- #40

- Joined

- Jan 18, 2010

- Messages

- 16,105

- Reaction score

- 9,062

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Canon/3D, CR-10, CR-10S, KP-3

Thanks @ninj...Shell thickness looks good - 3mm (rather than 0.3mm), which makes good sense for your lamp.