- Joined

- Jan 18, 2010

- Messages

- 15,792

- Reaction score

- 8,824

- Points

- 453

- Location

- Residing in Wicklow Ireland

- Printer Model

- Canon/3D, CR-10, CR-10S, KP-3

I think you should go back to the very start again because you have introduced too many variables

and you now can’t isolate your original problem properly.

Pop in a brand new set of OEM cartridges and don’t run any cleaning cycles first,

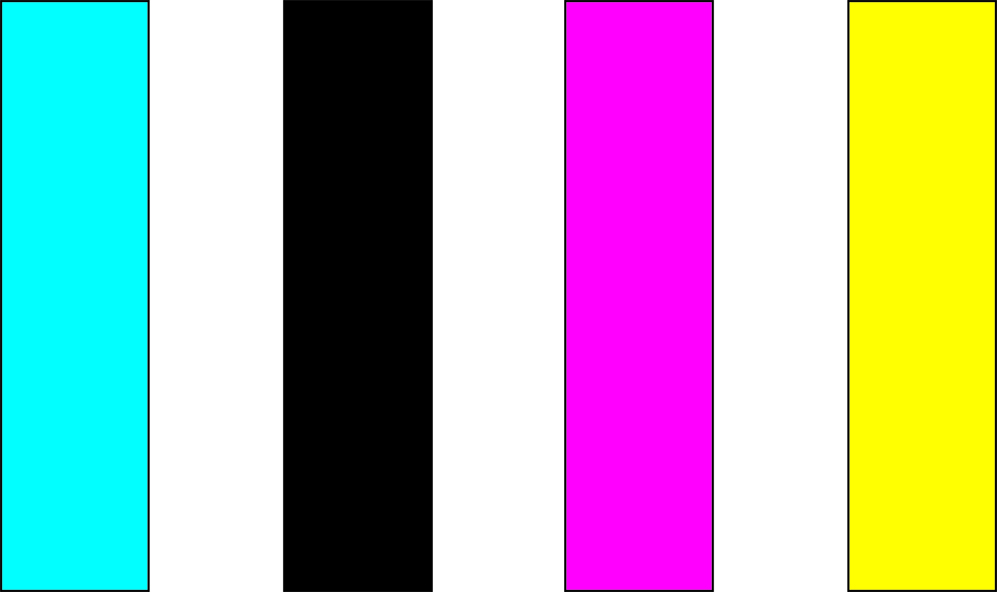

then just run a standard nozzle check then print off one sheet with four

2.5 cm x 10 cm colour swatches and see how they turn out. (Use this one)

If you’re test print-out is not 100% then your only alternative at this stage is to get a new print head and hopefully you haven’t damaged your logic board with all of the testing and cleaning on your damaged print head..

and you now can’t isolate your original problem properly.

Pop in a brand new set of OEM cartridges and don’t run any cleaning cycles first,

then just run a standard nozzle check then print off one sheet with four

2.5 cm x 10 cm colour swatches and see how they turn out. (Use this one)

If you’re test print-out is not 100% then your only alternative at this stage is to get a new print head and hopefully you haven’t damaged your logic board with all of the testing and cleaning on your damaged print head..