BlackSea

Printing Apprentice

- Joined

- Aug 7, 2018

- Messages

- 8

- Reaction score

- 6

- Points

- 16

- Printer Model

- WF 7710

Hey guys, first post here  First of all let me just say I am glad to be part of this community, and although until now I have not really participated in the talk here through input and mainly read and learnt, this forum and community is a great knowledge base and a wonderful discussion platform.

First of all let me just say I am glad to be part of this community, and although until now I have not really participated in the talk here through input and mainly read and learnt, this forum and community is a great knowledge base and a wonderful discussion platform.

Recently I have bought a new printer, adding to the ones which I already have. It is a WF 7710 with a CISS installed. I printed until now a couple of hundreds A3 sheets with it (about 250) doing various tests with various papers. Mostly I bought this as a digital sollution to try and make it work with offset paper. Here are some of my results which I would like to discuss with you. I use Inktec Durabrite pigments in the printer and I tested it on various offset paper, mostly double coated(on both sides) 64x90 cm which cuts in a convenient 32x45 offset paper, both glossy and semi matte. The largest gsm the device allows I found to be 300 gsm , and even that is a struggle as there is some rubbing from the feeding and transport mechanism onto the paper which kinda leaves some barely visible marks and the ink is not put down properly. I think a safe wight, for those who need thicker cardstock is 270 max.

Now I was very curious about the way in which the ink and the printer would react with this paper. From the media types found in the default Epson driver (I am using MacOS, Win driver seems to have some extra options - like Short Grain Paper, for extra thick, which I do ot have so don't know if the 300gsm would work better with that) I found that HQ plain papers and Thick work best. The profiles for various Epson specialty papers like matte, Ultra Glossy, Premium, Presentation,etc. I found that they give bad colour accuracy compared to my calibrated iMac and blotchyness in printing. That being being said, here are some samples below using 130gsm double coated fine offset paper , kinda glossy but not mirror-like glossy

From the printer menu, the settings which I used and enabled are - Unidirectional, Ink Drying time -Longest, Thick Paper-On; from the computer again Thick Paper&Envelopes-On and High Speed - Off;

from the menu - Paper Type= HQ Plain Papers; fed from both the cassete and rear tray; Quality=Highest;

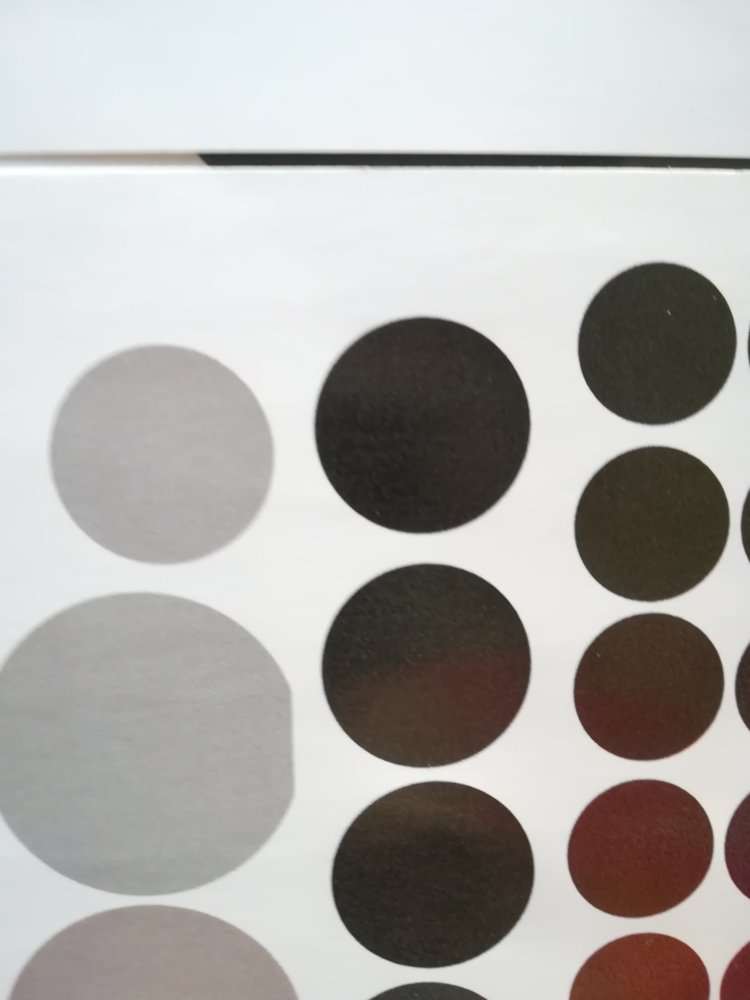

With no color correction from the driver here is a sample of a print of some swatches which I created myself in Photoshop, A3, 300dpi

The sheet on the left is printed with the file in sRGB profile, and no colour correction in driver; the file on the right is printed after conversion to EuroScale Coated V2, and some lifting of the shadows +a bit of saturation. The photo is not exactly perfect but suffice to say that the file on the left has about 75-80% color accuracy compared to what is displayed, the file on the right is at about 90% colour accuracy to what is displayed . So the conversion to the profile does seem to help with colour accuracy. There gamut seems to be limited in the shadow region , so these have to be lifted. Some more samples

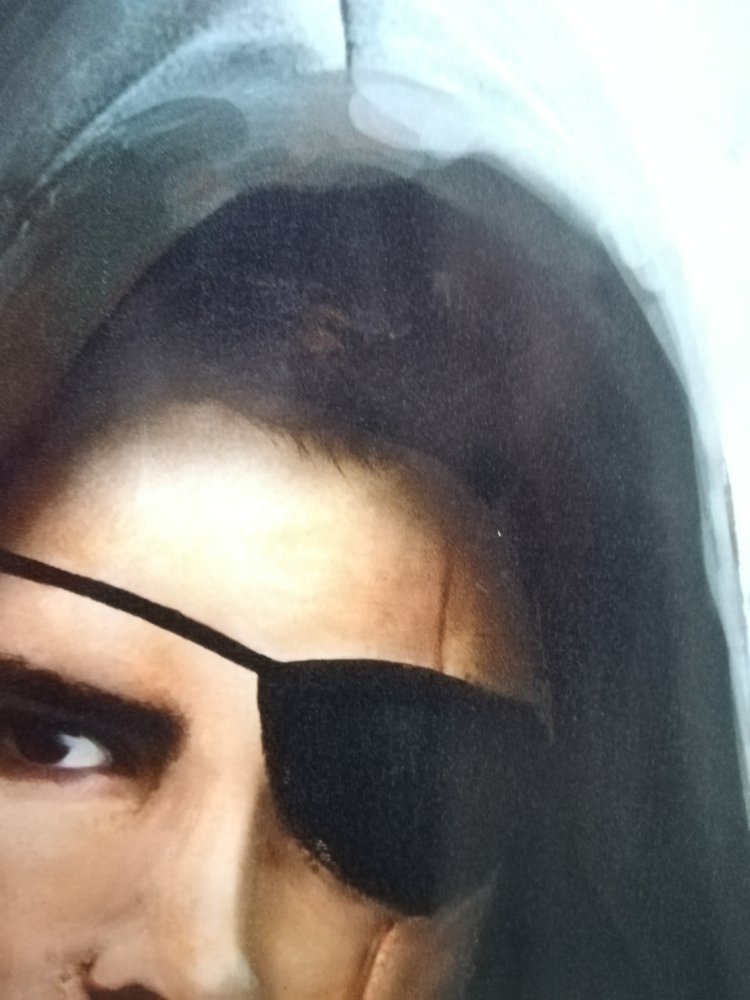

As you can see from these there is a certain grainyness in solid colours, especially visible in the dark regions. Here are some more photos, from samples printed, of a digital artwork and from a photo

Again the shadows exhibit such grainyness. Kinda looks like ink pooling to me, but maybe I'm wrong since I am no great expert and still learning . Now I know this ink and machine were not specifically designed to work with this paper but i am thinking of ways to improve it. When the ink I currently have in it will run out I am thinking of using some Ultrachrome ink insead. What do you guys think? Would that improve this? Or what other suggestions do you have?

Next week I will be able to put up some samples using linen texture offset paper, 220 and 270 gsm... Overall I am generally pleased with the printer, and I think right now the ink in it is the weakest link in the chain.

Also the samples above look a bit worse than in reality in those photos, as the shots are made with a phone camera... The printer can do photos and digital artwork, good just not excellent/extraordinary. But I feel it can do better, that is why I'm thinking of ways to improve

Thanks a lot for your patience to read this loooong post and if you have any suggestions, ideas, feedback I'd love to hear them.

and if you have any suggestions, ideas, feedback I'd love to hear them.

Recently I have bought a new printer, adding to the ones which I already have. It is a WF 7710 with a CISS installed. I printed until now a couple of hundreds A3 sheets with it (about 250) doing various tests with various papers. Mostly I bought this as a digital sollution to try and make it work with offset paper. Here are some of my results which I would like to discuss with you. I use Inktec Durabrite pigments in the printer and I tested it on various offset paper, mostly double coated(on both sides) 64x90 cm which cuts in a convenient 32x45 offset paper, both glossy and semi matte. The largest gsm the device allows I found to be 300 gsm , and even that is a struggle as there is some rubbing from the feeding and transport mechanism onto the paper which kinda leaves some barely visible marks and the ink is not put down properly. I think a safe wight, for those who need thicker cardstock is 270 max.

Now I was very curious about the way in which the ink and the printer would react with this paper. From the media types found in the default Epson driver (I am using MacOS, Win driver seems to have some extra options - like Short Grain Paper, for extra thick, which I do ot have so don't know if the 300gsm would work better with that) I found that HQ plain papers and Thick work best. The profiles for various Epson specialty papers like matte, Ultra Glossy, Premium, Presentation,etc. I found that they give bad colour accuracy compared to my calibrated iMac and blotchyness in printing. That being being said, here are some samples below using 130gsm double coated fine offset paper , kinda glossy but not mirror-like glossy

From the printer menu, the settings which I used and enabled are - Unidirectional, Ink Drying time -Longest, Thick Paper-On; from the computer again Thick Paper&Envelopes-On and High Speed - Off;

from the menu - Paper Type= HQ Plain Papers; fed from both the cassete and rear tray; Quality=Highest;

With no color correction from the driver here is a sample of a print of some swatches which I created myself in Photoshop, A3, 300dpi

The sheet on the left is printed with the file in sRGB profile, and no colour correction in driver; the file on the right is printed after conversion to EuroScale Coated V2, and some lifting of the shadows +a bit of saturation. The photo is not exactly perfect but suffice to say that the file on the left has about 75-80% color accuracy compared to what is displayed, the file on the right is at about 90% colour accuracy to what is displayed . So the conversion to the profile does seem to help with colour accuracy. There gamut seems to be limited in the shadow region , so these have to be lifted. Some more samples

As you can see from these there is a certain grainyness in solid colours, especially visible in the dark regions. Here are some more photos, from samples printed, of a digital artwork and from a photo

Again the shadows exhibit such grainyness. Kinda looks like ink pooling to me, but maybe I'm wrong since I am no great expert and still learning . Now I know this ink and machine were not specifically designed to work with this paper but i am thinking of ways to improve it. When the ink I currently have in it will run out I am thinking of using some Ultrachrome ink insead. What do you guys think? Would that improve this? Or what other suggestions do you have?

Next week I will be able to put up some samples using linen texture offset paper, 220 and 270 gsm... Overall I am generally pleased with the printer, and I think right now the ink in it is the weakest link in the chain.

Also the samples above look a bit worse than in reality in those photos, as the shots are made with a phone camera... The printer can do photos and digital artwork, good just not excellent/extraordinary. But I feel it can do better, that is why I'm thinking of ways to improve

Thanks a lot for your patience to read this loooong post